Talking Tanks –

Pentair is Europe’s Leader

Pentair confirms its position as the premier plastic water treatment tank producer in Europe.

When it comes to plastic water treatment tanks, Pentair can justly claim to be Europe’s Leader. These crucial components, at the heart of most water storage and treatment systems, come in all shapes, sizes and materials. But if your poly-tank was made in locally, there’s a fair chance it came from the Pentair manufacturing plant in Herentals, Belgium. Its 10,000 m2 factory is the only producer of blow moulded water tanks in Europe.

Immerse yourself in Pentair Water Treatment Tanks

The Herentals site has many decades of heritage in water tank production. Today its output includes tanks for all types of water storage, from structural pressure vessels to composite pressure tanks and simple storage tanks for mineral and brine solutions.

Where Herentals truly leads the way is in plastic tank production, utilising blow moulding and roto-moulding to supply thousands of tanks each year to the industrial and domestic markets in Europe and beyond.

Herentals Operations Manager, Staf Snyers, lives and breathes tank production and knows the business inside out. “For tanks sized 5”–21” diameter, blow moulding is ideal – quick, accurate and efficient. Plastic is melted and extruded into a hollow mould before air is blown into the centre forcing the plastic to the shape. For larger tanks, up to 79”, rotational moulding (rotomolding) is preferred. Huge moulds, filled with polyethylene, are tumbled in an oven until the perfect tank is cooked”.

“As water treatment systems have advanced and aging systems have been replaced, demand for safer, longer-lasting plastic tanks has surged. As their popularity and demand has increased Pentair, Europe’s only home-grown supplier of blow-moulded tanks, has been investing in the future.”

New extrusion blow moulding line –

investing in the future

Pentair has just spent big! A new €1.7M blow moulding line at Herentals, will come on-stream in April 2021. Sven Engelen, Pentair Manufacturing Engineering Manager explained the thinking behind the investment.

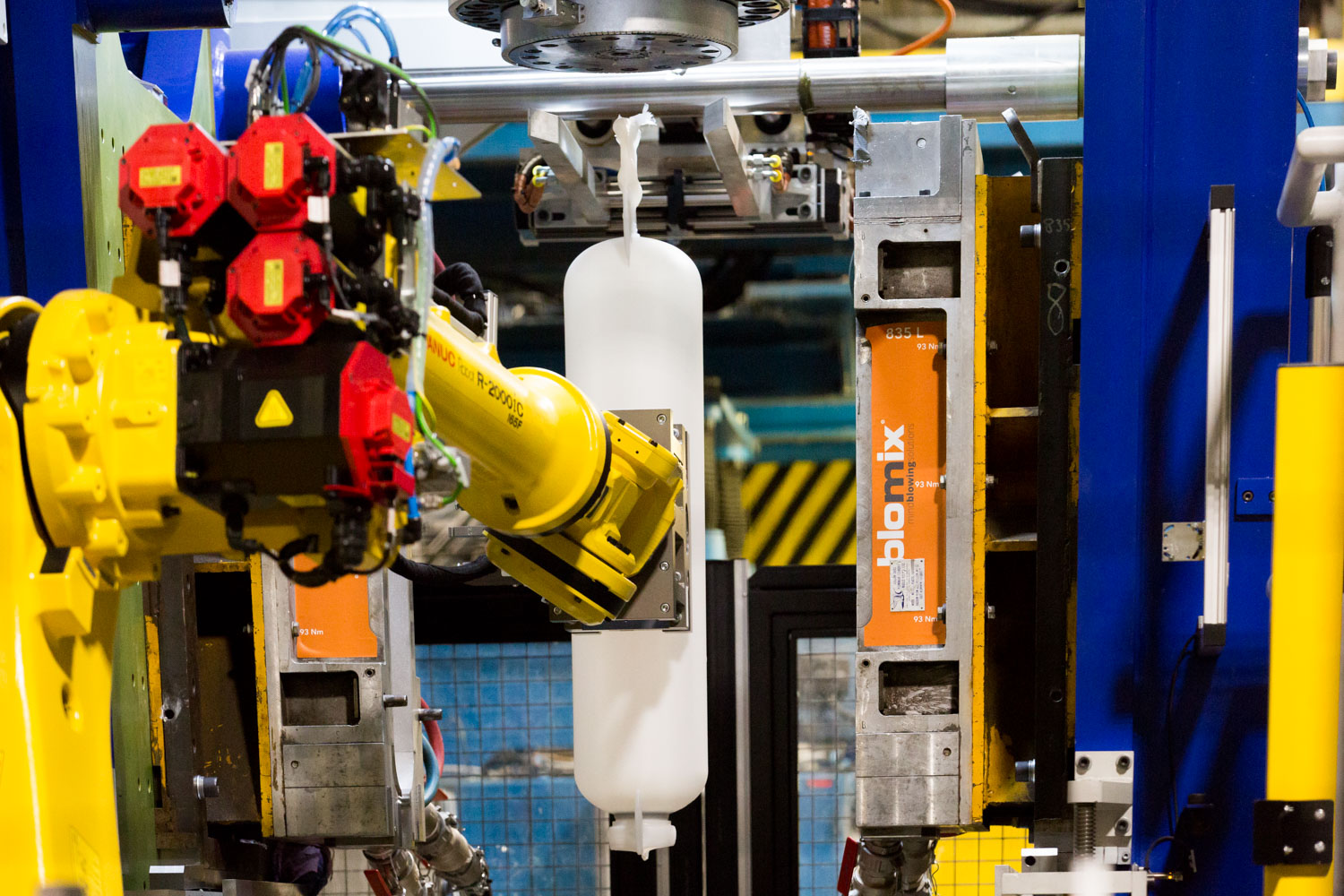

“At Pentair, we are always looking at ways we can increase output without compromising quality. Looking at the market and demand, we recognised the need for a new blow moulding machine and started our plans in 2019. Historically we have had three machines roughly aligned to different tank sizes – small, medium and large. But technology moves on and we wanted to replace our main workhorse with the very latest in blow moulding production – complete with automation and robotics to control and feed the production line.”

“While the end product may look simple, blow moulding is a highly complex process,” Sven continued. “We are not dealing with small plastic bottles here … these are large vessels. Little wonder no-one else is doing this for water treatment tanks in Europe.”

“It is not just the blow moulding engine that is new. We have worked with local automation specialists whose robotics will literally ‘take on the heavy lifting’. Robots will feed and run the machine, further increasing quality, consistency and throughput.”

“It’s been quite a journey,” says Sven. “Everyone here has been involved in the success; maintenance, service, production and quality control have all played a big part. Two years on and our installation is complete. The new machine is now commissioned, we are in the final testing stages and we will go live at the beginning of April 2021. The whole team is very excited – it’s like welcoming a new member of the family.”

New tank production line marks a step change

Steven Van Campenhout, who heads up component sales for Pentair Europe, sees this new machine as a step-change for Pentair. “Mid-sized tanks represent a big part of our output and are a vital component in the systems our customers install. Tanks cannot afford to fail, so quality is everything. Our new blow moulding machine represents a real step-change and raises Pentair manufacturing quality even higher in the European market. It will improve the accuracy and consistency of our tanks, way beyond what was previously possible.”

As well as higher quality, Pentair is confident that it will now be able to offer its European customers an improved service in terms of stock and supply. Orders will be fulfilled much faster. And, as the only major water tank manufacturer in Europe, that’s got to be worth talking about!”