Content

News & Events

-

Autotrol: A DNA of simplicity and reliability

Miridon is one of the largest water treatment companies in Estonia. With a background in industrial water treatment plants, it recognised early the need for reliable domestic water treatment in a region associated with water high in iron and hardness. Residential water softening and water filtration became a target for the business. The company researched the valve market and quickly concluded that there was one stand-out contender for this new enterprise: Autotrol. -

Pentair People: Herentals production team for WellMate tanks enjoy feeling the pressure.

We wrote recently about the Pentair strategic decision to establish a production line for WellMate, its flagship pressure boosting vessel, at its tank manufacturing plant in Herentals in Belgium. The relocation had many upsides for European customers. These included a considerably reduced lead time for orders, more stock availability, better alignment with European Directives for pressure equipment and ultimately a lower carbon footprint as local manufacturing considerably reduces the emissions generated by shipping containers of empty tanks across the Atlantic.

News 1 / 2

Remember to log in to see more news depending on your profile!

-

News

Autotrol: A DNA of simplicity and reliability

Miridon is one of the largest water treatment companies in Estonia. With a background in industrial water treatment plants, it recognised early the need for reliable domestic water treatment in a region associated with water high in iron and hardness. Residential water softening and water filtration became a target for the business. The company researched the valve market and quickly concluded that there was one stand-out contender for this new enterprise: Autotrol.

Miridon is one of the largest water treatment companies in Estonia. With a background in industrial water treatment plants, it recognised early the need for reliable domestic water treatment in a region associated with water high in iron and hardness. Residential water softening and water filtration became a target for the business. The company researched the valve market and quickly concluded that there was one stand-out contender for this new enterprise: Autotrol. -

News

Pentair People: Herentals production team for WellMate tanks enjoy feeling the pressure.

We wrote recently about the Pentair strategic decision to establish a production line for WellMate, its flagship pressure boosting vessel, at its tank manufacturing plant in Herentals in Belgium. The relocation had many upsides for European customers. These included a considerably reduced lead time for orders, more stock availability, better alignment with European Directives for pressure equipment and ultimately a lower carbon footprint as local manufacturing considerably reduces the emissions generated by shipping containers of empty tanks across the Atlantic.

We wrote recently about the Pentair strategic decision to establish a production line for WellMate, its flagship pressure boosting vessel, at its tank manufacturing plant in Herentals in Belgium. The relocation had many upsides for European customers. These included a considerably reduced lead time for orders, more stock availability, better alignment with European Directives for pressure equipment and ultimately a lower carbon footprint as local manufacturing considerably reduces the emissions generated by shipping containers of empty tanks across the Atlantic. -

News

Regulatory compliance. An integral part of the Pentair package.

How do you choose a product? Quality, reliability, availability and, of course, price all score high in procurement surveys. Surprisingly few mention ‘regulatory compliance’. Possibly because it can be taken for granted – especially in the highly regulated water treatment industry in which we operate.

How do you choose a product? Quality, reliability, availability and, of course, price all score high in procurement surveys. Surprisingly few mention ‘regulatory compliance’. Possibly because it can be taken for granted – especially in the highly regulated water treatment industry in which we operate. -

News

Pentair. ‘Making Better Essential’.

Here we review the good progress being made towards achieving the Pentair social responsibility strategic targets and showcase how its European operations are playing their part. Pentair has a long history of innovation that has made a positive impact on people and the planet. The decisions we make, the products we create, the solutions we offer, and the partnerships we form, are opportunities to make the world better. We believe that making life better for people and the planet, through smart, sustainable, water solutions, is essential. Indeed, the belief in ‘Making Better Essential’ now guides our social responsibility efforts and programme.

Here we review the good progress being made towards achieving the Pentair social responsibility strategic targets and showcase how its European operations are playing their part. Pentair has a long history of innovation that has made a positive impact on people and the planet. The decisions we make, the products we create, the solutions we offer, and the partnerships we form, are opportunities to make the world better. We believe that making life better for people and the planet, through smart, sustainable, water solutions, is essential. Indeed, the belief in ‘Making Better Essential’ now guides our social responsibility efforts and programme. -

News

Automation transforms manufacturing processes at Pentair

The Fleck turbine meter may be a tiny component, but it has a huge story to tell. This small yet vital sub-assembly is fitted to most Fleck residential valves and it measures the volume of water which passes through them, informing the valve controller of the optimal time for regeneration. That refresh only happens as and when it is needed, without its turbine meter a softener may unnecessarily waste a huge amount of water and salt.

The Fleck turbine meter may be a tiny component, but it has a huge story to tell. This small yet vital sub-assembly is fitted to most Fleck residential valves and it measures the volume of water which passes through them, informing the valve controller of the optimal time for regeneration. That refresh only happens as and when it is needed, without its turbine meter a softener may unnecessarily waste a huge amount of water and salt. -

News

Pentair People: Operations Supervisor Giulio Benvenuti is making his mark.

It would be hard not to be impressed by the passion and enthusiasm of Giulio Benvenuti. He takes his inspiration from working at Pentair and inspires those around him. Giulio only joined the company in 2021 as a Production Planner but has rapidly risen to supervising the operational production of the company’s valve range – a big responsibility on young shoulders. However, he relishes the task and is repaying the trust shown in him. We talked to Giulio about life at Pentair and what makes it so special for him.

It would be hard not to be impressed by the passion and enthusiasm of Giulio Benvenuti. He takes his inspiration from working at Pentair and inspires those around him. Giulio only joined the company in 2021 as a Production Planner but has rapidly risen to supervising the operational production of the company’s valve range – a big responsibility on young shoulders. However, he relishes the task and is repaying the trust shown in him. We talked to Giulio about life at Pentair and what makes it so special for him. -

News

Pentair Europe – vocal about sourcing local

‘Local-for-local sourcing’ improves quality, efficiency and flexibility at Pentair Europe For a business committed to European manufacturing for European markets, it should come as no surprise that 80% of the Pentair Europe annual shopping basket is sourced here on this continent. The Pentair credo, ‘Made in Europe for Europe’ should perhaps read ‘Buying and Producing in Europe, for Europe.

‘Local-for-local sourcing’ improves quality, efficiency and flexibility at Pentair Europe For a business committed to European manufacturing for European markets, it should come as no surprise that 80% of the Pentair Europe annual shopping basket is sourced here on this continent. The Pentair credo, ‘Made in Europe for Europe’ should perhaps read ‘Buying and Producing in Europe, for Europe. -

News

Groupe E & Pentair - a long and fruitful partnership

Pentair and Groupe E’s Water unit have been working together for many years in the field of water treatment for residential and industrial systems. Malik Seydoux (Head of the Water unit at Groupe E) and Benito Duran (Head of the Sanitary Water team) took time out to talk about the experience of working with Pentair.

Pentair and Groupe E’s Water unit have been working together for many years in the field of water treatment for residential and industrial systems. Malik Seydoux (Head of the Water unit at Groupe E) and Benito Duran (Head of the Sanitary Water team) took time out to talk about the experience of working with Pentair. -

News

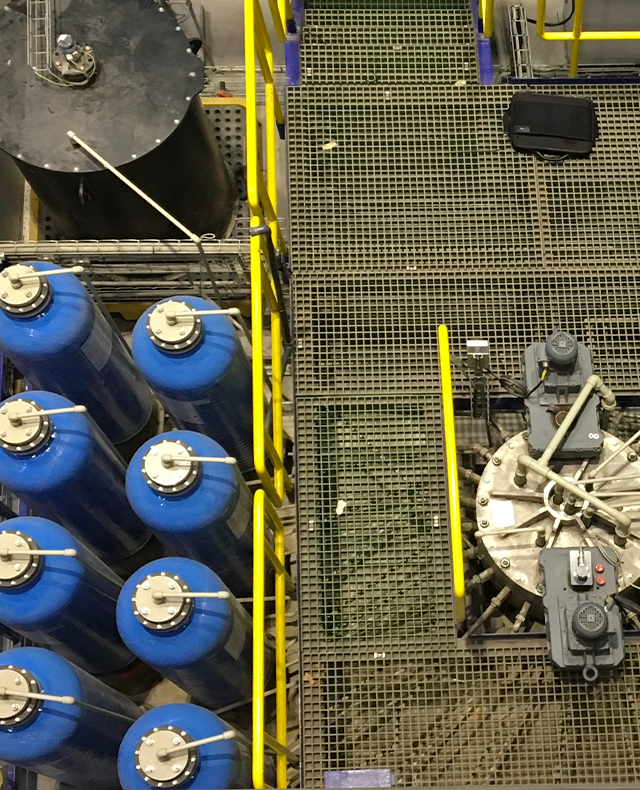

Huge flow rates demand huge tanks

Pentair Supertanks are first choice for CCIX provider PuriTech. For those of us who marvel at how smart engineering can mimic a simple process from nature, look no further than ‘countercurrent ion exchange’. Exchanging properties between liquids flowing in opposite directions is a core biological process and happens all around us – even in our own blood circulation system. And just as heat can be exchanged between counterflowing liquids, so can the chemical constitution through the exchange of ions, commonly used in applications such as water softening.

Pentair Supertanks are first choice for CCIX provider PuriTech. For those of us who marvel at how smart engineering can mimic a simple process from nature, look no further than ‘countercurrent ion exchange’. Exchanging properties between liquids flowing in opposite directions is a core biological process and happens all around us – even in our own blood circulation system. And just as heat can be exchanged between counterflowing liquids, so can the chemical constitution through the exchange of ions, commonly used in applications such as water softening. -

News

New Welding Technology is Hot News in Pisa

Ongoing plant investment improves reliability, speed, availability, accuracy and safety Investment continues apace at Pentair’s Centre of Manufacturing Excellence with the recent arrival of new hot-plate welding machines. Commissioned to support the 2023 relocation of global Autotrol production to Europe, this new technology is proving transformational. But like any new machinery it has been subjected to the most rigorous validation before being pressed into service. Project leader, Marco Calatroni discusses the drivers behind the upgrade and the positive impact they are making for Pentair and its customers.

Ongoing plant investment improves reliability, speed, availability, accuracy and safety Investment continues apace at Pentair’s Centre of Manufacturing Excellence with the recent arrival of new hot-plate welding machines. Commissioned to support the 2023 relocation of global Autotrol production to Europe, this new technology is proving transformational. But like any new machinery it has been subjected to the most rigorous validation before being pressed into service. Project leader, Marco Calatroni discusses the drivers behind the upgrade and the positive impact they are making for Pentair and its customers.