Pentair delivers European design

for European needs

Wherever you are in the world, tastes and needs vary. What goes in Tokyo or Turin might not cut it in Dublin or Delhi. One size doesn’t necessarily fit all and that can be as true in industrial design as it is in fashion. We spoke to the Pentair European Product Design Team about the process and how they cater for the tastes and needs in Europe.

Investing in European Design

Former head of design at Braun and arguably the world’s greatest industrial designer, Dieter Rams, once asked, “What makes good design?” He later answered his own question, citing key design principles. “Good design”, he argued, “should be innovative, useful, aesthetic, unobtrusive and thought-through in every detail.”

With a long history of engineering innovation, Pentair invests time and resource in good product design. And while all Dieter Rams’ design principals remain true, Pentair European product designers increasingly design with their home markets in mind.

Pentair 3D design process

At Pentair Europe, product design is the remit of a cross-functional team, comprising system and manufacturing engineers, operations and marketing. It is initially steered by a product manager.

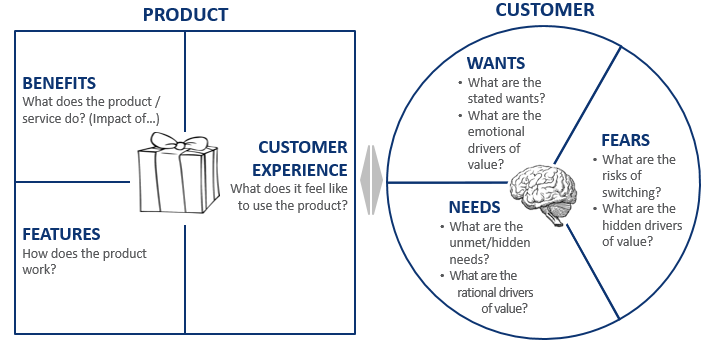

“At Pentair, we start with the problem and work backwards”, explains Gabriel Pieri, European Product Manager for Residential Systems. “We identify needs and create solutions that solve them in the best way. That ‘needs analysis’ is always front of mind. As a piece of industrial design our products must function well and look good with equal importance.”

Any design solution in development goes through a defined journey before it can hope to come to market. At Pentair this is a simplified into a three-stage process, incorporating three ‘D’s: Discover, Develop, Deploy.

Discover

Discovery is where we define the need we are trying to satisfy. It’s where we talk to users, look at the market and start to specify functions and features. And it’s about building a business case for the concept too.

In Discovery you cannot have too much input. We talk to end users, partners and field technicians. As we scope the product, it is where we might seek external input such as design studios or materials specialists. Many projects won’t get past this stage but for those that tick all the boxes, we move onto development.

Develop

This is a critical phase, largely owned by the Pentair Engineering team as they start to bring the concept to life.

As we move off the drawing board, materials are tested, protypes are built, and the product will be subject to an industry-standard Failure Mode and Effects Analysis (FMEA). Potential failures are identified and the impact of those failures rated and prioritised. It’s another refinement tool in the quest for the perfect design.

Deploy

If the product has met the criteria and the business case is still sound, then we have a green light for production. This is the deployment phase, and the operations team start to take a bigger role. Attention is turned to the logistics of mass production, the tools and production line resources that will be needed. It is an exciting time seeing a concept product reach this stage, bearing in mind that the design cycle may have taken years to get this far.

Continual improvement

Materials improve, technology evolves and of course tastes change.The Pentair design team are continually improving and innovating – driven by a passion for outstanding design that suits the needs of its European customers. And while they don’t shout about it, good design should never be taken for granted.

Case Study: Foleo Softeners –

Pentair European Design in Action

The Pentair Foleo is not just any water softener. It’s the physical representation of a design journey, to produce the best-in-class product on the market.

Pentair has an extensive portfolio of market-leading softeners, but the Pentair design team wanted to stretch the boundaries and imagine what could be possible. The design team felt there was room for a revolutionary look at softener design and that design would be driven by the particular needs of its European consumers.

The project was led by Matteo Rota, then the European Lead for Systems.

“In the Foleo discovery phase, our first port of call was to re-assess the needs of the European market.” recalls Matteo. “Using surveys, one-to-one meetings and focus groups, we talked to end users, dealers and installers about the pain points of water softeners. It was no surprise to hear that no-one likes filling water softeners. 25kg salt bags are big, heavy and there is always some salt that escapes where you don’t need it... and where do you store that unused salt left in the bag? We also reflected on what was working well in the existing range. The Pentair TopCab cabinet had a unique removable brine tank designed to make cleaning easier. The popular Pentair EVOLIO range featured a stylish top panel with a clever pop-up lid that helps make re-filling a one-person job.”

Time for a new look

“We really wanted to crack that refilling issue,” says Gabriel Pieri, Product Manager for the Foleo. “Keeping the salt duct opening as low, yet as big as possible was going to be important. And we needed to compromise between the smallest footprint and the largest salt bin – the bigger the bin, the more salt it would take. No one wants to fill a softener more often than they have to!”

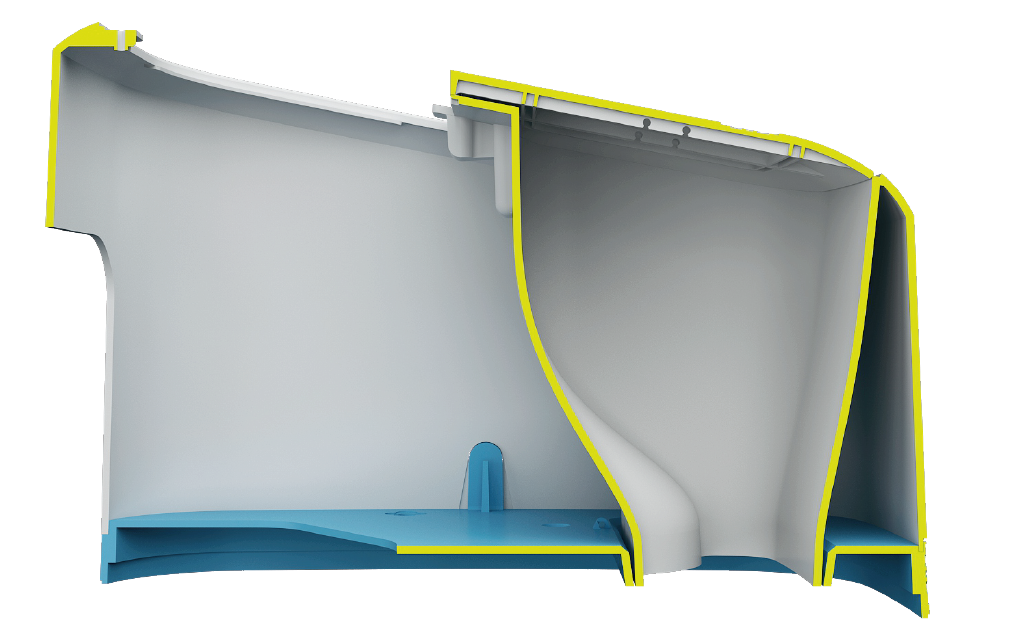

The design team started looking at ways of reducing the size without compromising on efficiency. It came down to a trade-off between the size of the brine tanks and the room for salt.

“To lower the height of the softener we started experimenting with shorter resin tanks, but with a larger diameter, to retain the maximum surface area,” continues Gabriel. “Ultimately, we opted for a nearly-square cabinet, with walls that were thick enough to give stability, yet light enough to lift, crucial to the new design.

Above all, softeners are increasingly on-display in kitchens and utility rooms – especially in Europe. They share space with streamlined appliances in hi-tec environments so any new softener would really need to look the part without shouting out.”

Underpinned by a sound functional and engineering specification, the design team started work on the ‘perfect’ softener. Step forward the Pentair Foleo softener range.

Foleo, an exemplar of good design

Matteo Rota pick up the story. “The Foleo uses specially developed shorter and wider resin tanks to reduce the cabinet height. The wide salt opening sits right on top and, by softener standards, it is relatively low so less struggling with heavy salt bags. And its relatively small size is good news, especially in Europe where homes are typically smaller than North America.

That said, the Foleo 20/30 swallows a full 25kg salt bag – so users don’t have to fill it so often or have part-used salt bags to store. The removable brine tank makes routine cleaning a breeze.”

To control the Foleo, the designers selected Pentair’s best performing valve, the Fleck 5800XTR, featuring an intuitive smart multitouch screen. Unlike some other valves that display meaningless numeric codes, it boasts a multi-language text display so users can easily understand the menus in their mother tongue. And its variable brining, using intelligent regeneration, is shown to reduce salt consumption by up to 50%, meaning cost saving and less of those annoying refilling trips.

The design team worked with multi-award-winning product designer Roberto Paoli to fine-tune the structure and style of the cover and cabinet. Roberto Paoli had collaborated previously with Pentair on the EVOLIO range to help solve the ergonomics of loading heavy salt bags. The Foleo salt bin lid was further refined providing a one-finger touch to open leaving both hands free to pour in the salt.

Together the Pentair design team and Roberto Paoli added integrated handles, optimised wall thickness and enhanced the clip design… every aspect of the range was refined until perfect.

Not only does the Foleo look the part, it is easy to use, fill and highly efficient to run, saving salt and ultimately cost for its owners. In every sense, Foleo can be said to be an outstanding product design and is a testament to the creativity of the European design team at Pentair.