ISO 9001. The difference is clear.

In Europe, Pentair has been compliant with quality management system ISO 9001 for over 25 years and has been keeping pace with this international standard at every step. We see ISO certification as an integral part of our whole manufacturing and operating ethos.

Lieven Wagemans, Quality Manager at Pentair explains why IS0 9001 is front and centre of the company’s quality culture. And, if you think ISO is just a lot of paperwork for a ‘rubber stamp’, you should listen to Lieven.

ISO 9001 is a quality management system, the ultimate objective of which is to provide customer confidence … confidence that a company’s products are high-quality, consistent and compliant.

First published in 1987, ISO 9001 has been frequently improved and updated to keep relevant to current thinking. Today’s ISO 9001 2015 standard encompasses quality management principles around leadership, process, continual improvement, risk-based thinking and, perhaps most importantly, customer focus.

“There are so many reasons why Pentair have always embraced ISO 9001”, explains Lieven Wagemans, in charge of Quality Management at Pentair Herentals.

“First off, when we get it right, we don’t just get a happy customer – we get them coming back, time, after time, after time. Meeting the standard is more than producing an outstanding product that works, it’s about delivering that quality, first time, every time and ISO 9001 gives us the framework to make that happen.”

ISO 9001 is an important tool in our customer-first focus

Lieven argues that quality doesn’t just mean a tank or valve being well made and being reliable. “Quality encompasses how we sell it, package it, service it, how we gain feedback, anticipate future needs … in fact every interaction with the customer provides an opportunity to add value and improve quality. And ISO 9001 is an important tool in our customer-first focus.”

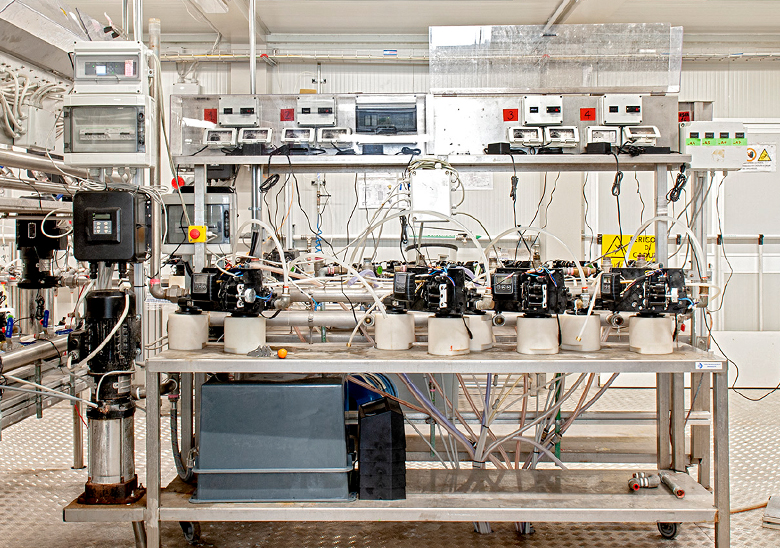

“An important principle of IS0 9001, especially for Pentair as a manufacturer, is adopting a process approach”, continues Lieven. “Through many interrelated processes we set key performance indicators that we continually track. If a target is not met, we can see it, better understand it and improve it. We use the ISO 9001 framework to optimise these manufacturing systems and our performance. It means we can guarantee to output consistent and high-quality products, efficiently, hour after hour, day in, day out.”

Innovation and continuous improvement is a guiding principle

Which leads Lieven onto continuous improvement – another guiding principle of ISO 9001. “As a leading innovator in the water treatment industry, it is essential for Pentair to react to change. To best serve our customers, we must innovate in technology, materials or market needs. That improvement might be anything from enhancements to an existing product based on customer feedback, to the commissioning of a major new production line. Whatever form it takes, we have a quality process in place that involves collecting data, then evidence-based decision making, with a healthy dose of risk-based thinking. It may sound obvious, but through ISO 9001 systems we can track, review and audit the planning, implementation, completion and results of our improvement projects.”

A good example would be the recent installation and commissioning of a new blow moulding machine at Herentals. It was a major exercise and involved multiple internal and external stakeholders. Leiven and his team used ISO 9001 change control principles to plan ‘up-front’ so there were no hidden surprises when it was up and running. “We went through a plan of dimensional control, process control and product testing, all to ensure that when we went live, the operating team knew exactly what to expect. There was a huge sense of pride across the whole Pentair team when the project rolled out, on time, on budget and with the expected quality.”

ISO 9001. Turning words into actions

Any organisation that boasts ISO 9001 as its Quality Management System must undergo a stringent independent audit before certification is granted.

Lieven explains, “We are independently audited across our European manufacturing sites to uphold our ISO 9001 certification. We are routinely inspected at least every three years and annually for more critical processes. The auditors will spend a few days at each site, talking to the machine operators, monitoring, measuring and satisfying themselves that the standard is being upheld before they will validate our ISO 9001 certificate.”

“Perhaps talking to the Pentair factory teams is the most important part of their audit. Here in our Herentals site I have a team of quality engineers and technicians that are responsible for implementing and administering ISO 9001 and it is the same in our Pisa plant. But these teams cannot succeed on their own. Everyone who works at Pentair has a role to play to make sure our quality standards are upheld. Which is why engaging and empowering people is another important principle of ISO 9001 that we take very seriously. Everyone at Pentair understands and is tasked to meet our quality objectives and ensure that ISO 9001 certification at Pentair is way more than just a certificate on the wall.”

“Ultimately, at Pentair we put our customers first. And above all, customers demand quality. ISO 9001 is instrumental in streamlining our quality management and that is reflected in the feedback we get from the field. But you don’t need to take my word for it – just ask our customers.”

ISO 9001 in Numbers

- 1987: Year ISO 9001 standards were first published

- 6-8 Years: frequency of review and revision of ISO standards

- 2015: Year of release of current ISO 9001 standard

- 1.2 Million: ISO 9001 certificates issued worldwide

- 185 Countries: Involved in updating ISO 9001 standards

TOP TIP: Choosing a new supplier? Beware of imitations.

If you are choosing a new supplier, ISO 9001 2015 is a great way to mitigate the risk of poor products and services. An ISO 9001 certificate will demonstrate that your supplier has a systematic approach to quality management that will ensure your expectations are met.

Ask to see their ISO 9001 2015 certificate. Remember, a supplier cannot claim its ‘products’ or ‘services’ meet ISO 9001 – it is awarded to the organisation. Check the date – getting certified is a process in itself, but maintaining certification is just as difficult. Also, look out for the authorised registrar (e.g. DNV, BSI, ABS etc.) as organisations are not permitted to award a certificate to themselves. If in doubt look for the Accreditation Body and check they are member of the International Accreditation Forum. Although rare, false claims of ISO 9001 certification are not unheard of, so make a thorough check!